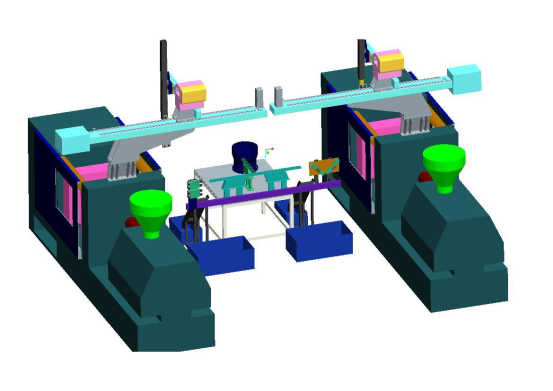

Equipment:

One set of automatic alignment system, two sets of shearing system and two sets of manipulator for taking out and embedding.

Scheme Description:

The two manipulators share a set of whole train system. After the finished product is taken out, the manipulator sends it to the shearing station to cut off the product and nozzle, and place the finished product and nozzle separately.

characteristic:

The system is suitable for the production of uniform embedded parts but differentiated products. At the same time, the molding of products has enough time for shearing.

The system uses a whole train system to minimize the cost, but requires sufficient production space. The system can realize full-automatic operation, and is equipped with automatic packaging system, which can meet the requirements of 24-hour uninterrupted operation without manual intervention.